Well Control; Pipe Milling Due to String Injection

It took three weeks of Engineering and Planning, 35 days of 24-hour operations to complete.

A major oil company drilled a Willrich horizontal well with a ball drop completion liner and stage tool. A service rig had been used to mill out the stage tool. Upon milling through the debris sub, the rig took a kick. A competitor's Rig Assist Unit was mobilized, and packers were run to isolate and find where the leak was. Upon tripping out of the hole, the Rig Assist Units slips failed and ejected seven joints of tubing. The well was secured with a snubbing annular bop.

Our Well Control Personnel mobilized and froze the wellbore. BOP doors were opened, and a folded pipe was confirmed. The Rig Assist Unit was stripped off, and the pipe was cut at the primary annular, and a 7-10 master valve was installed. The Service Rig and Rig Assist Unit demobilized with 80 JTS of tubing BHA and packers left in well.

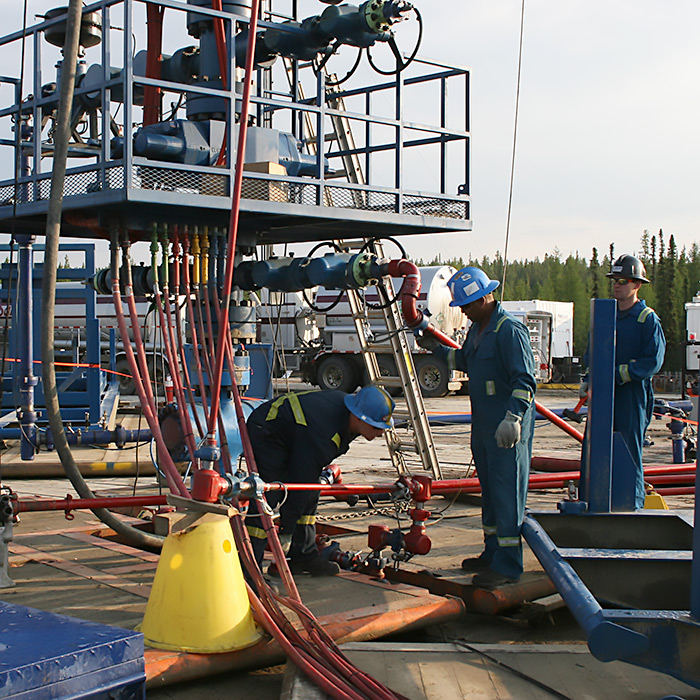

We rigged up a 285k Rigless Unit with substructure on top of the 7-10 master valve to a work floor height of 32m. The pipe was milled out of the stack with a 6-15/16" mill on custom 4" pipe centralized mill to mill through the master valve while holding 4,000 psi on the annulus. Once the pipe was milled into 4-1/2" casing, e-line was rigged up, and a camera was run to determine the pipe was round. We latched onto the tubing with an overshot, cut above the packer and installed permanent plugs. The tubing was snubbed out, and RIH with overshot to jar the packer free after being unable to free the string, pooh, RIH with wash pipe, and washover slips packer. Several runs were needed due to debris from the milling pipe in the stack. Once the slips were gone, RIH latched onto packer, jar free, pooh, RIH with venturi tool and cleaned the heel section to the top port.